Introduction

Polyols are a class of organic compounds characterized by carbon atoms covalently bonded to other atoms, including carbon-carbon and carbon-hydrogen bonds. Within this category, sugar alcohols stand out as a subgroup derived from sugars, which can occur naturally or be produced through industrial processes. These compounds have gained significant attention in various industries due to their versatile properties and applications.

One of the primary drivers propelling the global polyols market is the increasing demand for polyurethane foams. These foams find extensive use in numerous sectors, including automotive, construction, and furniture, owing to their exceptional insulation and cushioning properties. The construction and infrastructure sector, in particular, is a major contributor to the growing demand for polyols. As energy efficiency becomes a paramount concern in building design, polyols play a crucial role in the development of sustainable and energy-efficient insulation materials.

While the demand for polyols continues to rise, there are challenges that the industry faces. Environmental regulations and sustainability concerns are pushing manufacturers to develop more eco-friendly polyol formulations. This shift towards sustainability, although positive in the long run, may present initial hurdles and require investments in research and development.

Definition

Polyols, which are alcohols with several hydroxyl groups, are one of the primary basic ingredients used to make polyurethane. They are frequently utilised as essential raw materials in the production of a wide range of goods, including polyurethane foams, paints, adhesives, sealants, elastomers, and more. Petrochemicals and renewable resources like vegetable oils and sugar derivatives are the main sources of polyols. Based on their chemical composition, they may be divided into many categories, such as polyester polyols and polyether polyols. Each variety has unique qualities and is appropriate for various uses. Polyether polyols and polyester polyols are two different kinds of polyols. The polyols are utilised in a variety of applications, including coatings, adhesives & sealants, elastomers, flexible and rigid polyurethane foam, and others. Polyurethanes are adaptable, cutting-edge, and secure. They may be used for a wide variety of industrial and consumer goods to make our lives more convenient, pleasant, and ecologically friendly. Polyurethane comes in a variety of shapes and is composed of plastic material. It is chosen in a variety of applications and may be employed in several ways, such as stiff or flexible shapes, depending on the material. Repsol, which provides a portfolio of polyether polyols produced with homegrown technology and a wide range of alternatives, is one such polyol.

Challenges in polyols market

The polyols market faces several challenges that can impact its growth and operations. These challenges include:

- Environmental Regulations and Sustainability Concerns: Increasing environmental regulations and a growing focus on sustainability are putting pressure on the polyols industry to develop more eco-friendly and sustainable products. Manufacturers need to invest in research and development to create polyols with reduced environmental impacts, which can be a costly and time-consuming process.

- High Production Costs: The production of polyols can be expensive, especially when using eco-friendly processes or bio-based feedstocks. High production costs can limit the competitiveness of polyols in the market, especially when compared to conventional petrochemical-based alternatives.

- Fluctuations in Raw Material Prices: The cost of raw materials for polyols production, such as feedstocks and catalysts, can fluctuate significantly. These price fluctuations can affect the overall production costs and profit margins for polyol manufacturers.

- Technological Limitations: Developing innovative polyol formulations that meet industry-specific requirements can be challenging due to technological limitations. Manufacturers need to invest in research and development to overcome these limitations and stay competitive in the market.

- Performance Requirements: End-user industries have stringent performance requirements for polyols, especially in applications like construction and automotive. Meeting these performance standards while also addressing sustainability concerns can be a complex task.

- Market Competition: The polyols market is competitive, with multiple manufacturers vying for market share. This competition can lead to price wars and margin pressures, making it challenging for companies to maintain profitability.

- Supply Chain Disruptions: Disruptions in the supply chain, whether due to natural disasters, geopolitical factors, or other unforeseen events, can impact the availability of raw materials and disrupt production schedules.

Expansion rate in polyols market

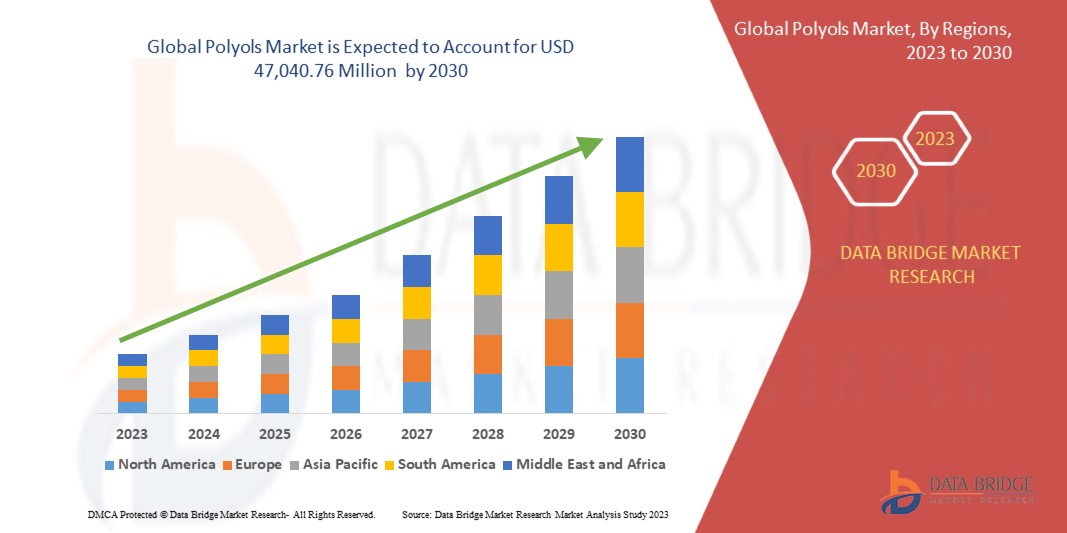

- Data Bridge Market Research’s analysis reveals a promising outlook for the global polyols market, with projections indicating substantial growth. By the year 2030, it is anticipated that the market will attain a remarkable value of USD 47,040.76 million, reflecting a robust Compound Annual Growth Rate (CAGR) of 5.6% during the forecast period.

- Several key factors are contributing to this positive trajectory. The versatility of polyols, with applications spanning various industries, is a major driver of market growth. Polyols find use in sectors as diverse as construction, automotive, packaging, and textiles, owing to their valuable properties and functions. This wide-ranging applicability is fueling demand across industries.

- Additionally, growing awareness and emphasis on sustainability are propelling the adoption of eco-friendly polyols. As environmental concerns continue to gain prominence, manufacturers are investing in the development of polyols with reduced environmental impact. This aligns with stringent environmental regulations and consumer preferences for sustainable products.

Growing Demand for Polyols in the Polyurethane Industry

The global polyurethane industry is experiencing a significant surge in the demand for polyols, a crucial component in the production of polyurethane materials. This escalating demand is driven by several key factors that underscore the pivotal role of polyols in the industry.

- Versatility in Applications: Polyurethane is a versatile polymer widely used in various sectors, including construction, automotive, furniture, insulation, coatings, and adhesives. Polyols serve as one of the essential building blocks for polyurethane production, enabling the customization of polyurethane materials to meet specific application requirements.

- Insulation and Energy Efficiency: In the construction sector, polyurethane foam insulation is highly sought after for its exceptional thermal insulation properties. Polyols are a critical component in the formulation of rigid polyurethane foam, which is extensively used to enhance energy efficiency in residential and commercial buildings. As global efforts to reduce energy consumption and greenhouse gas emissions intensify, the demand for energy-efficient insulation materials grows, driving the need for polyols.

- Automotive Lightweighting: The automotive industry is increasingly turning to polyurethane materials, including polyurethane foams and elastomers, to reduce vehicle weight and improve fuel efficiency. Polyols play a pivotal role in the development of lightweight, durable, and comfortable automotive components, such as seating, interior trim, and soundproofing materials.

- Furniture and Bedding Comfort: In the furniture industry, polyurethane foams with varying levels of softness and resilience are used to create comfortable seating and bedding products. Polyols contribute to the production of flexible and viscoelastic foams, enhancing the comfort and durability of mattresses, sofas, and chairs.

- Coatings and Sealants: Polyurethane coatings and sealants are prized for their protective and adhesive properties. These materials find applications in industries ranging from automotive coatings to architectural coatings and industrial sealants. Polyols play a critical role in formulating coatings and sealants that provide corrosion resistance, weatherproofing, and adhesion strength.

- Customization and Performance: The ability to customize polyurethane materials using different types of polyols allows manufacturers to tailor the final product’s performance characteristics. This flexibility is highly valued in industries where specific performance criteria must be met, such as temperature resistance, fire resistance, or mechanical strength.

- Sustainability and Bio-Based Polyols: Growing environmental awareness has prompted the development and adoption of bio-based and eco-friendly polyols. These alternatives, derived from renewable sources such as vegetable oils or biomass, align with sustainability goals and address environmental concerns. As sustainability gains prominence, the demand for these bio-based polyols is expected to rise further.

For more information about market visit

https://www.databridgemarketresearch.com/reports/global-polyols-market

Data Bridge Market Research provides customized research reports tailored to the specific needs of their clients. These reports offer comprehensive insights into market trends, competitive landscapes, and growth opportunities. Data Bridge Market Research covers a wide range of industries, including healthcare, technology, chemicals, and more. They have subject matter experts who possess deep industry knowledge.