The global polyisobutylene market size stood at a value of more than USD 3.09 billion in 2023. The market is further expected to grow at a CAGR of 5.03% in the forecast period of 2024-2032 to attain a value of over USD 4.73 billion by 2032. Polyisobutylene, or PIB, is a remarkable polymer with a wide range of applications across various industries. Its unique properties make it indispensable in areas such as automotive, construction, pharmaceuticals, and more. In this blog post, we will delve into the world of polyisobutylene, exploring its history, properties, applications, market trends, and growth prospects.

I. Historical Perspective

Polyisobutylene has a fascinating history that dates back to its discovery in the early 20th century. Initially, it was developed as a synthetic rubber to replace natural rubber, which faced supply shortages during World War I. The versatility of PIB quickly became apparent, leading to its adoption in various industries.

During World War II, the demand for PIB surged as it found applications in fuel additives and lubricants for aircraft and vehicles. This period marked a turning point in the recognition of PIB’s potential beyond rubber replacement.

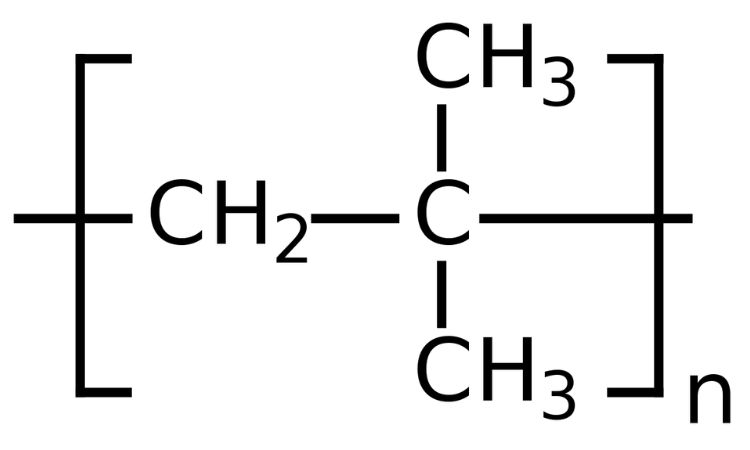

II. Properties and Characteristics of Polyisobutylene

Polyisobutylene boasts several unique properties that contribute to its widespread use. It is a synthetic elastomer characterized by:

- Excellent impermeability to gases and moisture.

- Exceptional resistance to chemicals and oxidation.

- High viscosity and molecular weight options.

- Low glass transition temperature.

- Good electrical insulation properties.

These properties make PIB ideal for a multitude of applications where impermeability, flexibility, and chemical resistance are crucial.

III. Applications of Polyisobutylene

Polyisobutylene’s versatility shines through in its applications across diverse industries:

Automotive: PIB is used extensively in the automotive sector, primarily in the production of tires, where it enhances the tire’s air retention and puncture resistance. Additionally, it plays a crucial role in the formulation of fuel and lubricant additives, contributing to engine performance and longevity.

Construction: In the construction industry, PIB finds use in sealants and adhesives due to its strong adhesive properties and resistance to weathering. It helps create durable, airtight, and watertight seals in buildings.

Pharmaceuticals: PIB is utilized in pharmaceutical formulations as a tablet coating material. It provides controlled release properties and improves the stability of certain drugs.

Food Packaging: PIB is employed as a sealant layer in food packaging materials to maintain product freshness and extend shelf life by preventing the ingress of air and moisture.

IV. Market Size and Growth

As mentioned earlier, the global polyisobutylene market has witnessed substantial growth, with a market value exceeding USD 3.09 billion in 2023. Projections indicate that this growth will continue, with a CAGR of 5.03% expected during the forecast period of 2024-2032, leading to a market value exceeding USD 4.73 billion by 2032.

This remarkable growth can be attributed to several factors:

1. Increasing Automotive Production: The automotive industry’s expansion, driven by rising global demand for vehicles, has a direct impact on PIB demand. As automakers strive to enhance fuel efficiency and tire performance, PIB’s role in tire manufacturing and fuel additives becomes increasingly crucial.

2. Growing Construction Activity: The construction industry’s growth, particularly in emerging markets, fuels the demand for sealants and adhesives. PIB’s excellent adhesive properties make it a preferred choice in construction applications.

3. Pharmaceutical Advancements: The pharmaceutical sector’s continuous innovation drives demand for PIB in drug formulations. The controlled-release properties of PIB contribute to improved drug delivery systems.

4. Expanding Food Industry: The food packaging industry’s focus on preserving the freshness and quality of packaged products sustains the demand for PIB-based sealants in food packaging materials.

V. Key Trends in the Polyisobutylene Market

The polyisobutylene market is dynamic, with several key trends shaping its trajectory:

1. Sustainable Production: Growing environmental concerns have prompted manufacturers to explore sustainable production methods for PIB. Research into bio-based PIB and more eco-friendly processes is ongoing.

2. Advanced Tire Technology: The tire industry is constantly evolving, with an emphasis on fuel efficiency and sustainability. PIB’s role in tire manufacturing continues to evolve with the development of self-sealing and airless tires.

3. Pharmaceutical Innovations: PIB is gaining prominence in pharmaceuticals, with ongoing research to optimize its use in drug delivery systems, including transdermal patches and oral formulations.

4. Regulatory Compliance: Stringent regulations related to food packaging, chemicals, and environmental standards are influencing PIB formulations and applications. Manufacturers are adapting to ensure compliance.

VI. Environmental and Regulatory Considerations

The increasing emphasis on sustainability and environmental consciousness has put the spotlight on PIB production and usage. While PIB itself is inherently stable and inert, there are concerns about its manufacturing processes and potential environmental impact. Manufacturers are actively working to address these concerns through more eco-friendly production methods and improved recycling processes.

Regulatory bodies are also closely monitoring the use of PIB, particularly in applications related to food packaging and pharmaceuticals, to ensure safety and compliance with stringent standards.

VII. Future Growth Prospects

The future of the polyisobutylene market looks promising. With ongoing research and development efforts, the market is expected to expand further. Key growth drivers include:

1. Sustainable Practices: The adoption of more sustainable and environmentally friendly production methods will not only meet regulatory requirements but also appeal to environmentally conscious consumers and industries.

2. Technological Advancements: Ongoing research into PIB applications, such as tire technology and drug delivery, is likely to lead to innovative solutions and increased demand.

3. Emerging Markets: The penetration of PIB into emerging markets, where industries are experiencing rapid growth, will provide new opportunities for market expansion.

4. Industry Collaboration: Collaboration between PIB manufacturers and industries that rely on PIB-based products will drive product development and market growth.

VIII. Case Studies

To illustrate the practical applications and benefits of polyisobutylene, let’s look at a couple of case studies:

Case Study 1: Tire Manufacturing In the tire manufacturing industry, PIB is a critical component. Leading tire manufacturers have successfully leveraged PIB to improve tire performance and longevity. By using PIB-based inner liners, tires can maintain proper air pressure for longer periods, reducing the frequency of tire inflation and improving fuel efficiency. This technology has been widely adopted by major automotive companies, leading to increased demand for PIB in this sector.

Case Study 2: Pharmaceutical Industry The pharmaceutical industry relies on precise drug formulations to ensure the effectiveness of medications. PIB is used in controlled-release drug delivery systems, such as transdermal patches. One notable case is the development of nicotine replacement therapy patches for smoking cessation. PIB-based patches slowly release nicotine into the bloodstream, helping individuals quit smoking more effectively.

IX. Conclusion

The polyisobutylene market has witnessed remarkable growth, driven by its unique properties and diverse applications across industries. As the global economy continues to evolve, the demand for PIB is expected to rise, particularly in sectors like automotive, construction, pharmaceuticals, and food packaging.

As the market continues to expand, manufacturers and industries must remain committed to sustainability and regulatory compliance. Ongoing research and technological advancements will contribute to the continued growth and innovation within the PIB market.

Whether it’s improving tire performance, enhancing drug delivery systems, or sealing the buildings we live in, polyisobutylene continues to play a vital role in our daily lives. As we look to the future, it’s clear that the versatile polymer has even more to offer, promising a brighter and more sustainable future for various industries.