Temperature measurement is a critical aspect of various industries, from manufacturing to healthcare. In India, the production of contact temperature sensors has grown significantly over the years, with various types of sensors being developed to suit different applications. Let us understand the making of different types of contact temperature sensors in India and their wide-ranging uses.

Types of Contact Temperature Sensors

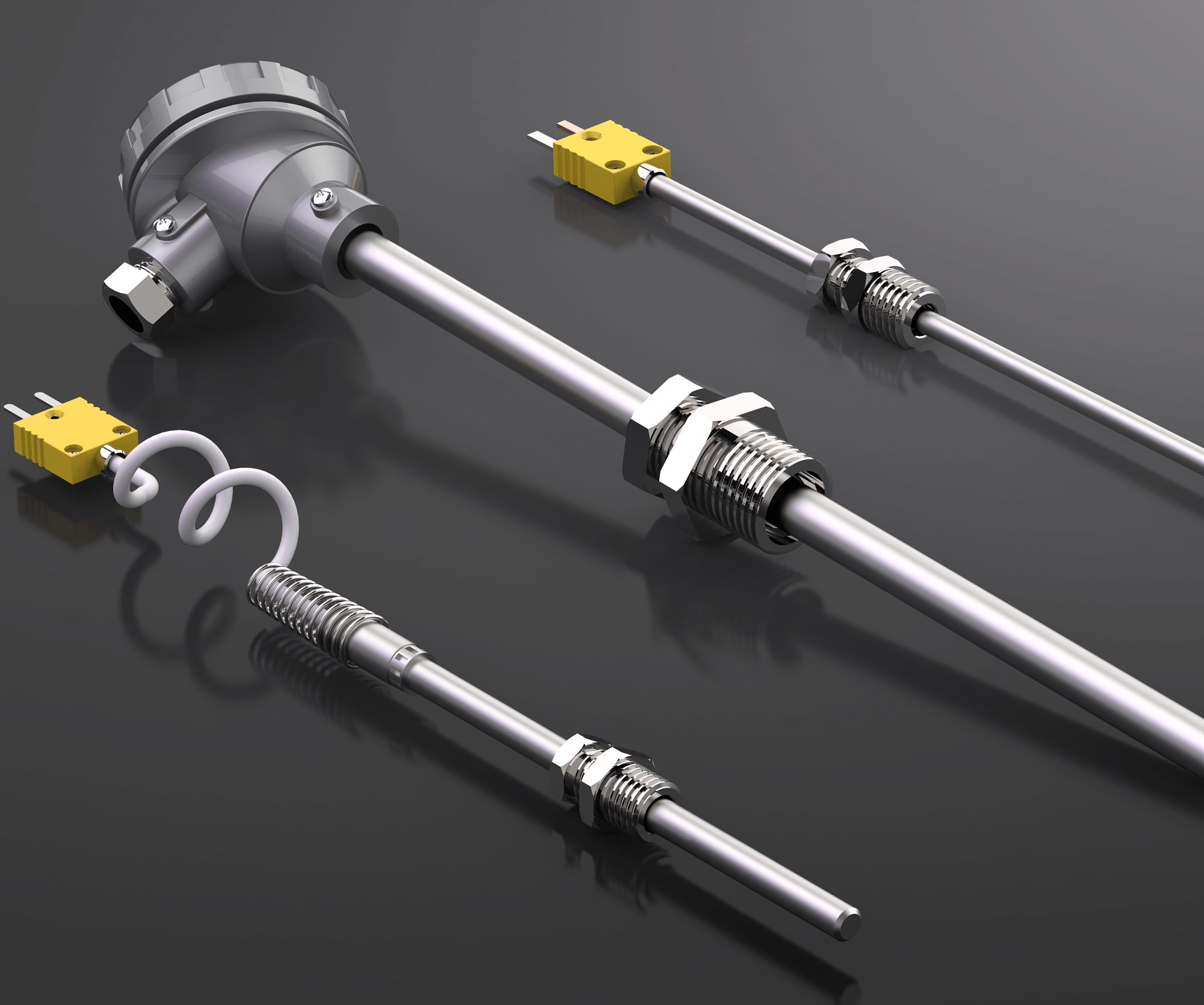

1. Thermocouples

Thermocouples are one of the most widely used contact temperature sensors. They consist of two different metal wires connected at one end. When exposed to heat, they generate a voltage proportional to the temperature difference between their hot and cold junctions. The highly manufactured types of thermocouples are K-type, J-type, and T-type, each suitable for specific temperature ranges and applications.

Example: In the steel industry, thermocouples are used to monitor the temperature of molten metal in furnaces. By precisely measuring the temperature, manufacturers can ensure that the steel is of the desired quality.

2. Resistance Temperature Detectors (RTDs)

RTDs are temperature sensors with a coil or wire made of a pure metal, often platinum. As temperature changes, the electrical resistance of the wire changes, allowing accurate temperature measurements. India has a strong manufacturing base for RTDs, and they are commonly used in various industries, such as pharmaceuticals, food, and automotive.

Example: In the pharmaceutical sector, RTDs are used in sterilization processes to ensure that drugs and medical devices are subjected to the correct temperature for disinfection, guaranteeing the safety and effectiveness of the products.

3. Infrared Temperature Sensors

Infrared temperature sensors, also known as non-contact temperature sensors, measure the thermal radiation emitted by an object. These sensors are becoming increasingly popular in India for their versatility and non-invasive nature.

Example: In agriculture, infrared temperature sensors are used to monitor crop temperatures. By assessing the temperature of crops, farmers can identify areas where irrigation is needed, optimizing water usage and improving crop yields.

The Making of Contact Temperature Sensors in India

1. Material Selection

The production of contact temperature sensors begins with careful material selection. For example, in the case of thermocouples, choosing the right combination of metals is crucial. Indian manufacturers source high-quality materials and alloys to ensure sensor accuracy and durability.

2. Manufacturing Processes

Manufacturers in India employ various techniques to create accurate and reliable temperature sensors. For thermocouples, the wire junctions are carefully welded or brazed to ensure a robust connection. For RTDs, the platinum wire is precision-wound and encapsulated to protect it from environmental factors.

3. Calibration and Testing

Every sensor must undergo rigorous calibration and testing to ensure its accuracy. Indian manufacturers invest in state-of-the-art calibration equipment to verify that the sensors provide precise temperature measurements.

4. Quality Control

Quality control is a fundamental part of the manufacturing process. Manufacturers in India adhere to international standards and guidelines to maintain the highest quality standards in the production of contact temperature sensors. This includes regular inspections, validation processes, and compliance with industry-specific regulations.

Applications of Contact Temperature Sensors in India

1. Industrial Processes

Contact temperature sensors are widely used in industries such as manufacturing and petrochemicals to monitor processes, control equipment, and ensure product quality. For instance, in the oil and gas industry, contact temperature sensors are used to measure the temperature of pipelines and equipment to prevent overheating and ensure safe operations.

2. Healthcare

In the healthcare sector, contact temperature sensors are indispensable for monitoring patient health. They are used in various medical devices like thermometers and incubators. For example, contact temperature sensors play a vital role in measuring patients’ body temperatures, helping to identify potential cases of infection.

3. Agriculture

In agriculture, temperature sensors are employed for environmental monitoring and precision farming. Farmers use these sensors to monitor soil temperature, air temperature, and crop temperature to make informed decisions about irrigation, planting, and crop health.

4. Environmental Monitoring

Contact temperature sensors are used in environmental applications to monitor temperature changes in water bodies, soil, and air. This data helps in assessing climate change, preserving ecosystems, and ensuring the safety of sensitive equipment in extreme conditions.

The production of contact temperature sensors in India has grown significantly, with a wide range of sensors available to cater to diverse applications. These sensors are crucial in maintaining product quality, ensuring safety, and improving efficiency across various sectors. As India continues to develop its manufacturing capabilities, it plays a vital role in contributing to the global demand for accurate and reliable contact temperature sensors. Whether in industrial processes, healthcare, agriculture, or environmental monitoring, contact temperature sensors are an integral part of modern society, helping us better understand and manage our world.